Arashi Journal Bearing Turbos

Arashi journal bearing turbos is composed with standard journal bearing center cartridge type like MHI, Toyota, IHI,…etc. Features of journal bearing include durability and stability, it manages shock and high boost better and it’s more affordable than the other systems.

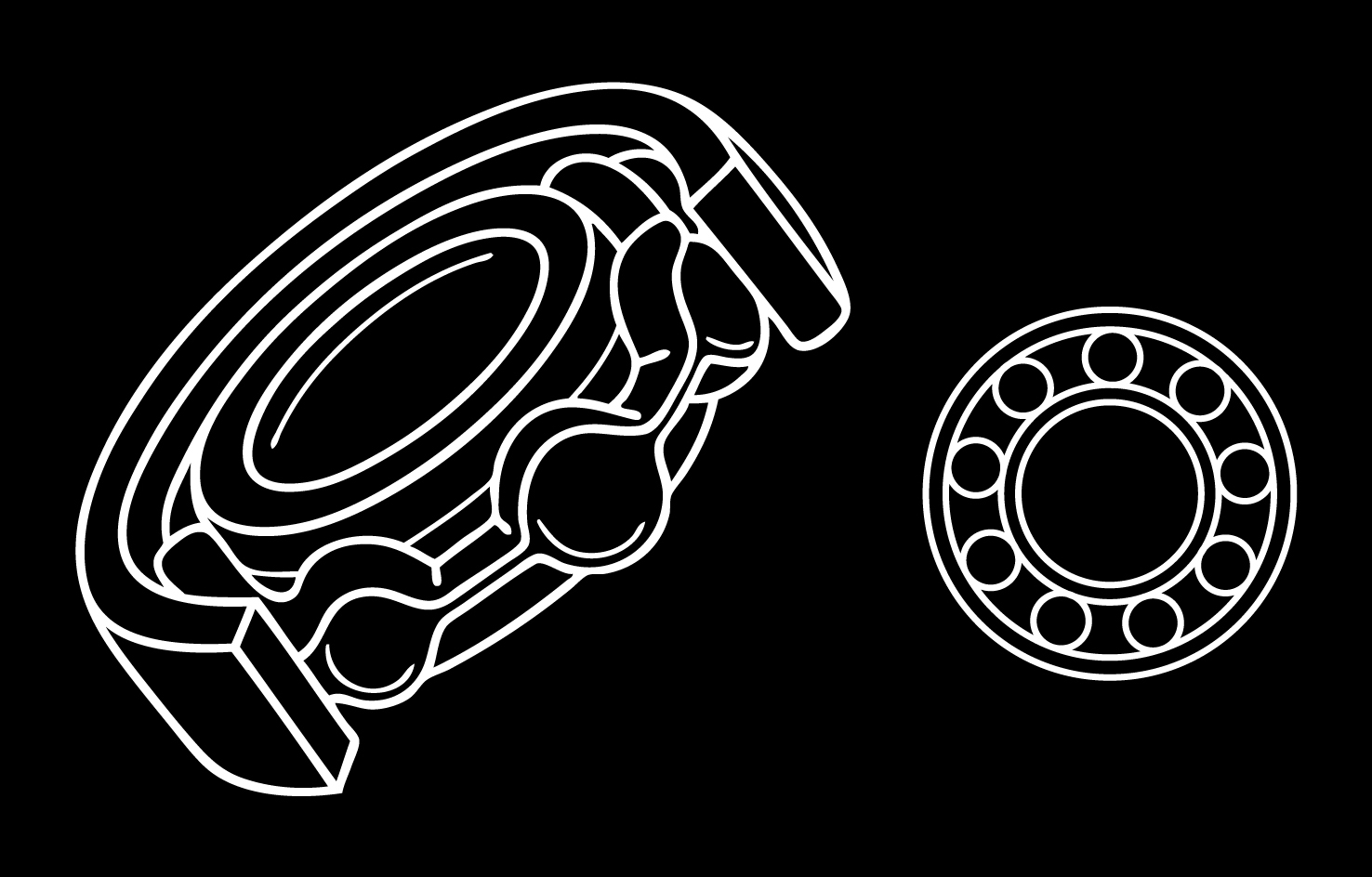

Kuro Ball Bearing Turbos

Kuro ball bearing turbos are like typical ball bearing turbos, they’re assembled with gt, gtx, gen ii, or g series wheel. They consume only half of the oil than journal bearing turbos and their spool is 15% faster than journal bearing turbos.

KBT Turbo

KBT turbo is our latest invention, it combines both journal bearing and ball bearing system by swapping journal bearing bush to ceramic ball bearing without having to change the oil and water line kits, however, a restrictor is required for ball bearing, it is included in the kit. KBT turbo is assembled with Japanese TD style wheels. Basically converting a TD style turbo into ball bearing turbo. Therefore has all the advantages combined together.

Skip to content

Skip to content